JUST PRECISION

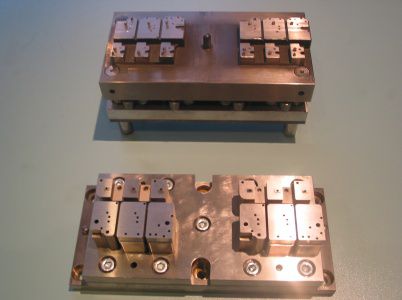

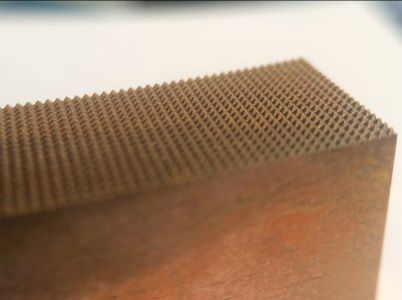

Cadcamatic disposes of an extensive range of machines for handling even the hardest of steel types: wire cutting and sink EDM (Charmilles, Makino), CNC milling, surface grinding and multi-tool turning etc. This allows us to produce most precision parts that are demanded by the current market or that we need in our moulds and dies, automations and machines.

By continually investing in new machines and technologies, Cadcamatic aims to remain an absolute pioneer.

It makes us more innovative, more efficient and simply better. JUST CUTTING EDGE

Our measuring chamber is air-conditioned. We verify the desired accuracy using a 3D measuring machine. Measuring can be done optically or tactilely. We measure our own precision parts or components supplied by the customer. If desired, we can provide you with an extensive measuring report.