SOLUTION-ORIENTED

Cadcamatic works with a well thought-out, stage-gate approval process, guaranteeing sufficient process stability. You can follow up on and approve the various steps within this process. If desired or required, we take care of the preproduction or the first production.

Cadcamatic is able to manufacture/adjust all precision parts in-house. We dispose of an extensive range of technology: wire cutting and sink EDM, CNC milling, surface grinding and multi-tool turning etc. An air-conditioned measuring chamber with a 3D measuring machine verifies and records the desired accuracy.

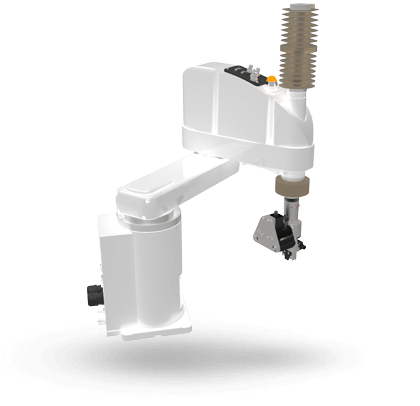

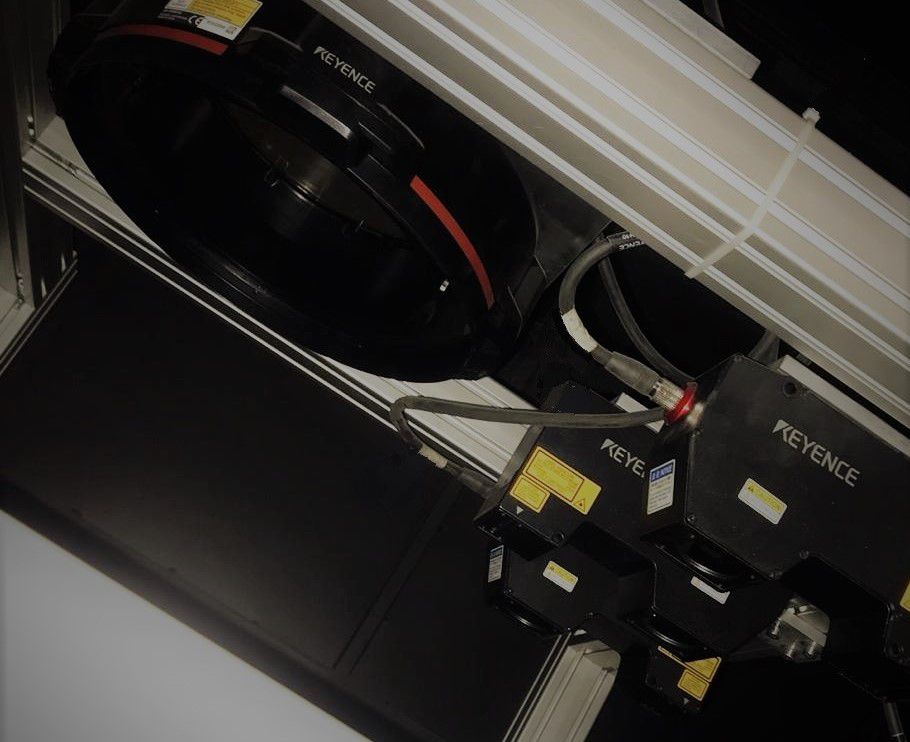

We integrate various types of robots, PLCs and vision systems in line with your wishes and the project’s requirements. As the machine assembly is done with and by our design engineers, we are able to handle the most complex processes in ever shorter lead times.

Cadcamatic pays a great deal of attention to a smooth process integration at your site. For example, we make sure that our engineers provide support on-site, we supply a complete information package, we take care of all legal documentation (CE certificates and construction files etc.) and we train your employees. Service after completion is guaranteed – no matter where you are located.